Start

End

A Seminar

On

“Advanced FEA”

At

Geethanjali Institute of Science and Technology (GIST)

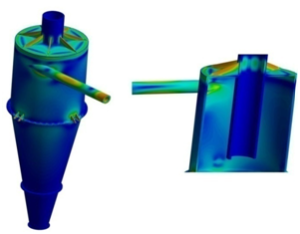

The department of Mechanical Engineering organized a one day Technical seminar on “Advanced FEA” by Mr.M.Srinivas, YuCAN Technologies, Banglore on 20-09-2018.The Principal of GIST, Prof. Dr. G.SubbaRao addressed the students regarding the importance of FEA and applications of advanced FEA in industry. The resource person discussed about This seminar was organized by Mechanical Engineering department to enhance the skills and increase the employability of the students. This seminar also addressed queries about fundamentals of design and analysis. 57 students of ME.(Mechanical) was substantial benefits from this seminar. Following discussions and demonstrations.

Typically, mechanics and heat transfer problems are initially tackled with analytical tools. Where the geometry and physics are sufficiently simple, this yields accurate results. Applying simplifications intelligently can increase the level of complexity which is possible to analyse. The reality of complex industrial products and processes is that simple physical relations are quickly replaced by complex partial differential equations and complicated geometries. Many resort to experimental testing of prototypes to bypass the knowledge gap. Doing so requires significant investment of time and resources and does not always yield the certainty which is sought. An alternate solution is the use of advanced computational tools such Finite Element Analysis (FEA). FEA’s main advantage is that it produces a much more detailed set of results than experimental investigations and is often quicker and less expensive.Fundamentally, it relies on the discretisation of the geometry to solve mechanical and thermal equations, effectively subdividing the structure in an assembly of simple (finite) elements. Instead of tackling a big problem directly, we divide it into smaller and more easily solvable problems and then get a unique result for the system as a whole. The discrete model is an approximation of the behaviour of the real physical structure. However, provided that the discretisation mesh is dense enough, the approximation is sufficient to accurately model reality.

The advantages of FEA :

- Comprehensive result sets, generating the physical response of the system at any location, including some which might have been neglected in an analytical approach.

- Safe simulation of potentially dangerous, destructive or impractical load conditions and failure modes.

- Optimal use of a model. Often, several failure modes or physical events can be tested within a common model.

- The simultaneous calculation and visual representation of a wide variety of physical parameters such as stress or temperature, enabling the designer to rapidly analyse performance and possible modifications.

- Extrapolation of existing experimental results via parametric analyses of validated models.

- Relatively low investment and rapid calculation time for most applications.