MECHANICAL ENGINEERING LABORATORIES

Department of Mechanical Engineering includes the following laboratories with modern and advanced equipment’s and software.

- Basic Engineering Workshop Laboratory

A workshop is a platform which provides the means and tools required for the manufacture of various goods. Students are exposed to hands on experience in a variety of operations like Carpentry, Welding, Fitting, Tin smithy, Casting, Forging, House wiring etc., catering to the needs of first year as well as higher semester students.

- Metallurgy & Materials Science Laboratory

Material Science Laboratory provides facilities for determining various properties of engineering materials, microstructure of both ferrous and non-ferrous materials etc., and also for performing various heat treatment processes.Laboratory equipped with microscopes, mounting presses, furnace etc.

- Mechanics of Solids Laboratory

Mechanics of Solids Laboratory focuses on the basic principles in the area of strength and mechanics of materials and structural analysis through a series of experiments. In this lab the experiments are performed to measure the properties of the materials such as impact strength, tensile strength, compressive strength, hardness, fatigue strength etc.

- Fluid Mechanics & Hydraulic MachinesLaboratory

In FMHM lab, the static and dynamic behavior of fluid flows are analyzed. The objectives of the experiments include determination of forces generated, when fluid flow takes place over a solid object, application of Bernoulli’s equation and the momentum – energy equations, viscosity measurement and engineering correlations. Also theoretical and experimental aspects are investigated with a particular emphasis on the industrial applications such as the design, the installation and the operation of hydraulic machines.

- Manufacturing Technology Laboratory

Manufacturing Technology Laboratory provides practical exposure to distinct primary manufacturing process like casting, welding & forming and its applications in various industries. Laboratory equipped with sand testing equipment, plastic molding setups, welding setups like arc welding, TIG welding and spot welding. Also furnished with press working tools.

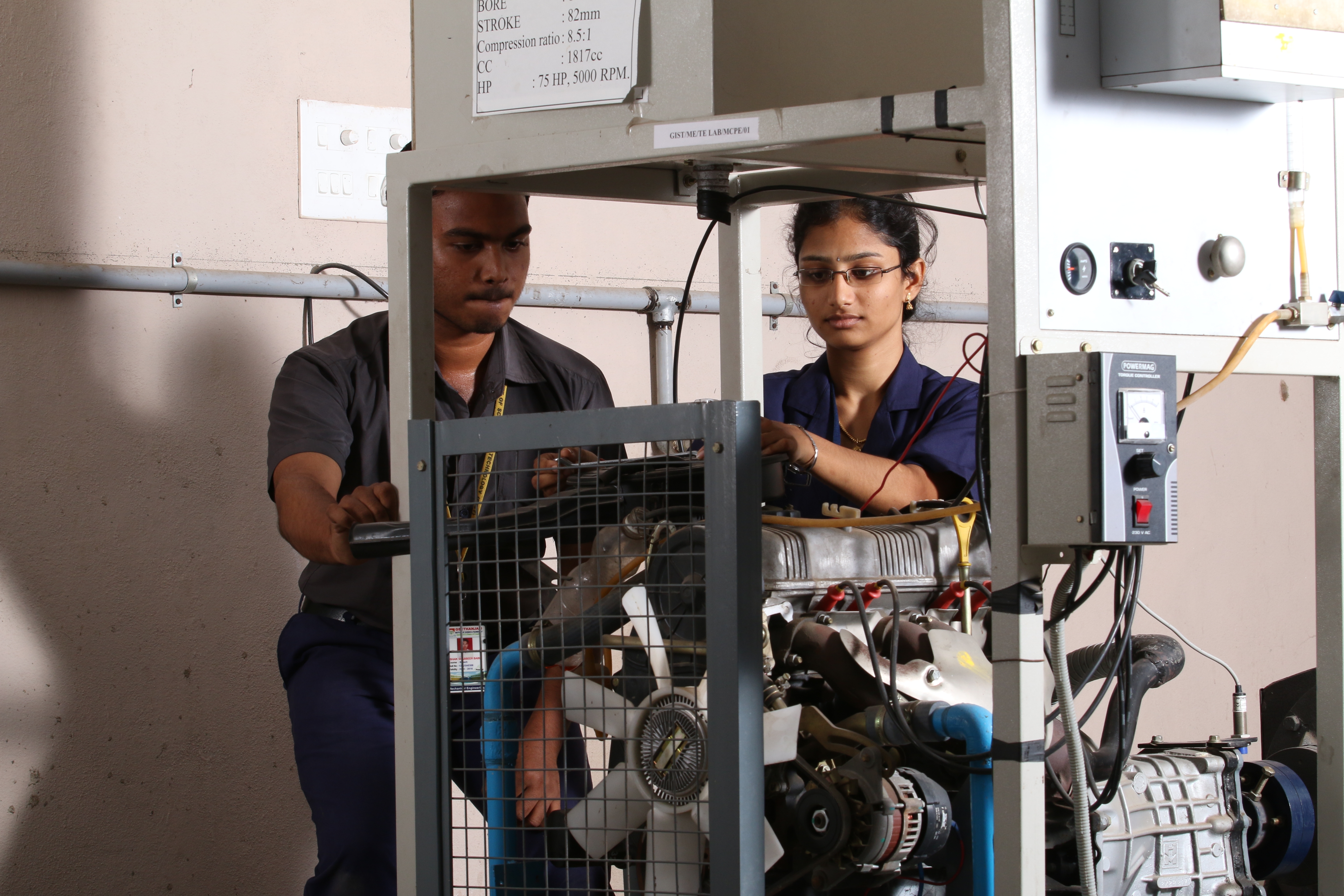

- Thermal EngineeringLaboratory

Thermal Engineering Laboratory is well-equipped and enables students to evaluate the performance characteristics of two stroke and four stroke diesel and petrol engines. The lab also contains basic parts of an engine like Carburetor, Fuel injection system, Engine cooling system, and the cut section models.

- Machine Tools Laboratory

Machine Tools laboratory is aimed at providing an introduction to the conventional metal cutting/material removal methods and practices. This laboratory will also provide ample opportunity for the students to acquire required skill in various machining operations on conventional machinery like lathe, shaper, planer, slotter, drilling and milling machine etc, .

- Heat TransferLaboratory

Heat Transfer laboratory lays emphasis on fundamental and industrial knowledge about modes of heat transfer, like conduction, convection and radiation, and their real time application.

- Metrology & InstrumentationLaboratory

Metrologyand Instrumentation Laboratory covers the working principle of the various measuring instruments. Students learn to select the appropriate instrument as per the requirement of the inspection process, and operate the same. This lab also enables the students to learn the methods of measurement of geometrical features like lengths, angles, flatness, parallelism, alignment, surface finish, and errors in gears and screw threads.

- CAD /CAM / CAELaboratory

CAD lab provides drafting & designing tools like AutoCAD, CATIA V5, Ansyssoftwares enables the students to meet the industry standards in Design and Manufacturing.CAM lab equipped with CNC lathe machine XLTURN and its programming to familiarize the students with precision machinery. CAElab is to aid in engineering analysis tasks. This lab facilitates high-performance computing for interactive CAD/CAM/CAE systems.